Mail Us: [email protected]

Call For Us: 0086-536-3295156

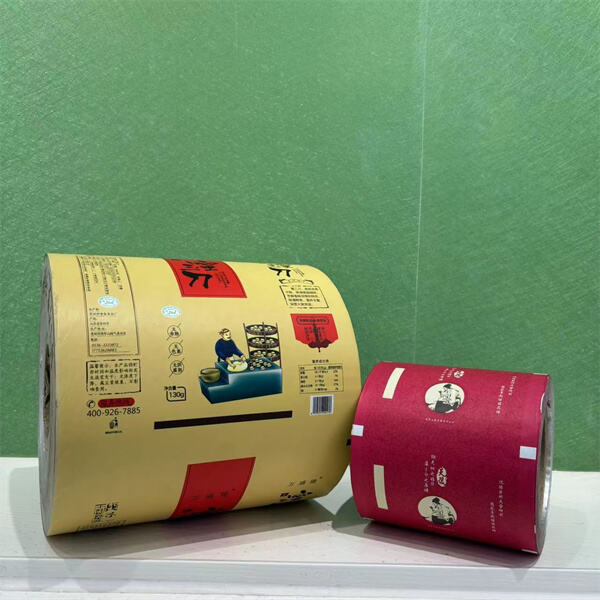

Rollstock Film, a Perfect Packaging Solution

Packaging is pivotal to the global production and transportation of goods. Today business have started focusing more on how to optimize their packaging in a way that it protect, preserve as well sell the value proposition of its product. Rollstock is one of the most common types of packaging solutions out there and for good reason, they are versatile and comparatively lower cost than other containers. In this Utomik rollstock article, we will show you its various benefits of using Roll Stock for Packaging to decrease packing costs as well as it is eco-friendly, how do Roll stock used in the Step by step guide and apply on not only food packaging but much more.

Rollstock Film: The Ideal Flexible Packaging Solution Rollstock film is one of the most adaptable and versatile packaging options on the market today, with an extensive range of advantages such as;

High Production: Rollstock film is produced in long rolls, allowing it to be the most cost-effective and advantageous type of packaging for all types of existing machinery.

Applicability: These films can be used for a wide range from rigid applications to flexible packing alike such as thermoforming, vacuum pouches with gas flush or modified atmosphere packaging through forming web and heat sealing film etc.

Design Flexibility: Rollstock film printing gives businesses the opportunity to create unique packaging designs which align with their brand, thus increasing recognizability.

Extended Product Shelf-Life: Another benefit from rollstock film is its barrier properties which can perfectly protect the products from oxygen, moisture and other conditions that may lead to degradation of product quality.

Economical Rollstock film is produced in bulk quantities, reducing the per-unit packaging cost and making it a more economical option for your products as compared to other packaging options.

Packaging costs are important for a business because they affect product distribution. This, in turn increases the cost of production and lowers quality - which does not work out too well financially for anyone involved; including you.

Determined Packaging Size: As we discussed earlier, choosing the correct dimensions of packaging has a huge impact on reducing material usage which will then lead to an overall decrement in costs related to both large scale as well mid/small quantity Folding Cartonent, Packing and Storage.

Cost-effective Packaging Choice: This is yet another way of choosing a rollstock film that can lead to much easier savings for the business.

Optimize the Packaging Layers: Save costs by creating a higher level of packaging, that won't damage your product in any way.

Sustainable Practices: Adopting eco-friendly and sustainable packaging practices not only save your costs but also lowers the burden on our environment.

Rising Awareness on Eco-friendly Packaging Driving MarketThe demand for biodegradable and recyclable packaging solutions has led to several projects from the manufacturers over innovation in the field of packaging. It offers a number of benefits, making it an environmentally friendly packaging solution:

Improved Recyclability: Since this packaging film has polyethylene as its main component, it is highly recyclable and therefore provides good disposal for the environment.

Reduced carbon footprint: The rollstock film is produced employing fewer amounts of energy, which reduces the emission of harmful carbons contrary to other packaging materials.

Renewable Material Utilization - Rollstock film can be made out of renewable, plant-based materials such as sugarcane to reduce dependence on non-renewables.

Waste reduction: By using rollstock film in customizable sizes, less material is wasted during the production process overall.

Everything you Need to Know About Rollstock Film Choosing

With a wide range of potential applications, the choice is not an easy one to make when it comes to Rollstock film. Rollstock Film SelectionThe most important thing to remember when choosing roll stock film for packaging is the following points:

Protective Barrier Properties: The barrier properties are indispensable to protect the products from moisture, oxygen and light.

Transparency: transparency is crucial in products that need to be visible for marketing.

Material Strength: Material strength is important, especially for heavier items as it provides the packaging integrity during transportation.

Environmental Impact: Evaluate how environmentally friendly the packaging materials are and if they fall in line with your company's sustainability principles.

Developing wider array of Applications not only limited to Food Packaging

Although rollstock film is most commonly used when it comes to food packaging, the application of this type of shrink bag into different areas goes beyond just that.

Medical Containers: Good for packaging medical devices and pharmaceuticals because it is protective and sterile

Beauty Products Packaging beauty care items, for instance shampoo and conditioner printing coverage fuel consumptionidity.

Electronic Appliances: It also safeguards your electronic devices against water and dust, Making it an excellent choice to packaging electronic gadgets. Read More

Thus, the role of rollstock film is summed as a modernised and profitable packaging solution being asked upon by businesses across different industries for its flexibility, customisation abilities and environmentally sustainable features. The use of rollstock film is an opportunity for businesses to save money, but it also helps make a dent in the carbon footprint left by their operation. Businesses should carefully consider several factors while picking rollstock film that aligns with their brand image and sustainability initiatives. Moreover, the uses of rollstock film stretch far and wide beyond just food packaging with a variety different applications across industries.

Automated flex-o-graphic printing gravure printing, solvent-free compounding machine dry compounding machines, extrusion compounding machine and online testing as well as other production equipment to aid customers in completing specific services to satisfy the rollstock film.

rollstock film has a big 30000 square meter manufacturing unit. The main focus of company comprises packaging film, packaging bags, and paper.

The business happens to be certified by ISO9001, QA and SGS. It really is loaded with a chemical and physical laboratory allows the company to monitor all facets of production to make sure it really is in line with the rollstock film of composite products.

We have an rollstock film customer team to make sure our customers can are able to get thier items quickly and also at a top-notch. Expert sales, design and after-sales workers readily available.